Have you ever asked yourself which type of valve is better for your project, a ball valve or a butterfly valve? This is a common question in industries where fluid flow needs to be managed in a safe and reliable way.

Both ball valves and butterfly valves are used widely, and each comes with its benefits. The good news is that choosing between them is not complicated once you understand how they work and what they are best suited for.

Utility Pipe Supply provides high-quality ball valves and butterfly valves that are essential for maintaining precise flow control in a wide range of projects. Whether you’re working on a commercial installation, industrial system, or residential upgrade, Utility Pipe Supply offers durable, reliable valve options designed to withstand demanding conditions. With their focus on performance and longevity, Utility Pipe Supply ensures that contractors and project managers have the dependable components they need to keep systems operating safely and efficiently.

Understanding Valves in Projects

Valves are important parts of any project where liquids, gases, or steam need to be controlled. They act like gates that can open, close, or adjust the flow as needed, and ball valves and butterfly valves are two of the most used options, and each brings its strengths to the table.

Both types are built for efficiency, safety, and long-term use, making them valuable for industries like construction, water treatment, oil, gas, and even simple plumbing systems.

When comparing them, it is not about one being better than the other. Instead, it is about choosing the one that fits the specific needs of your project.

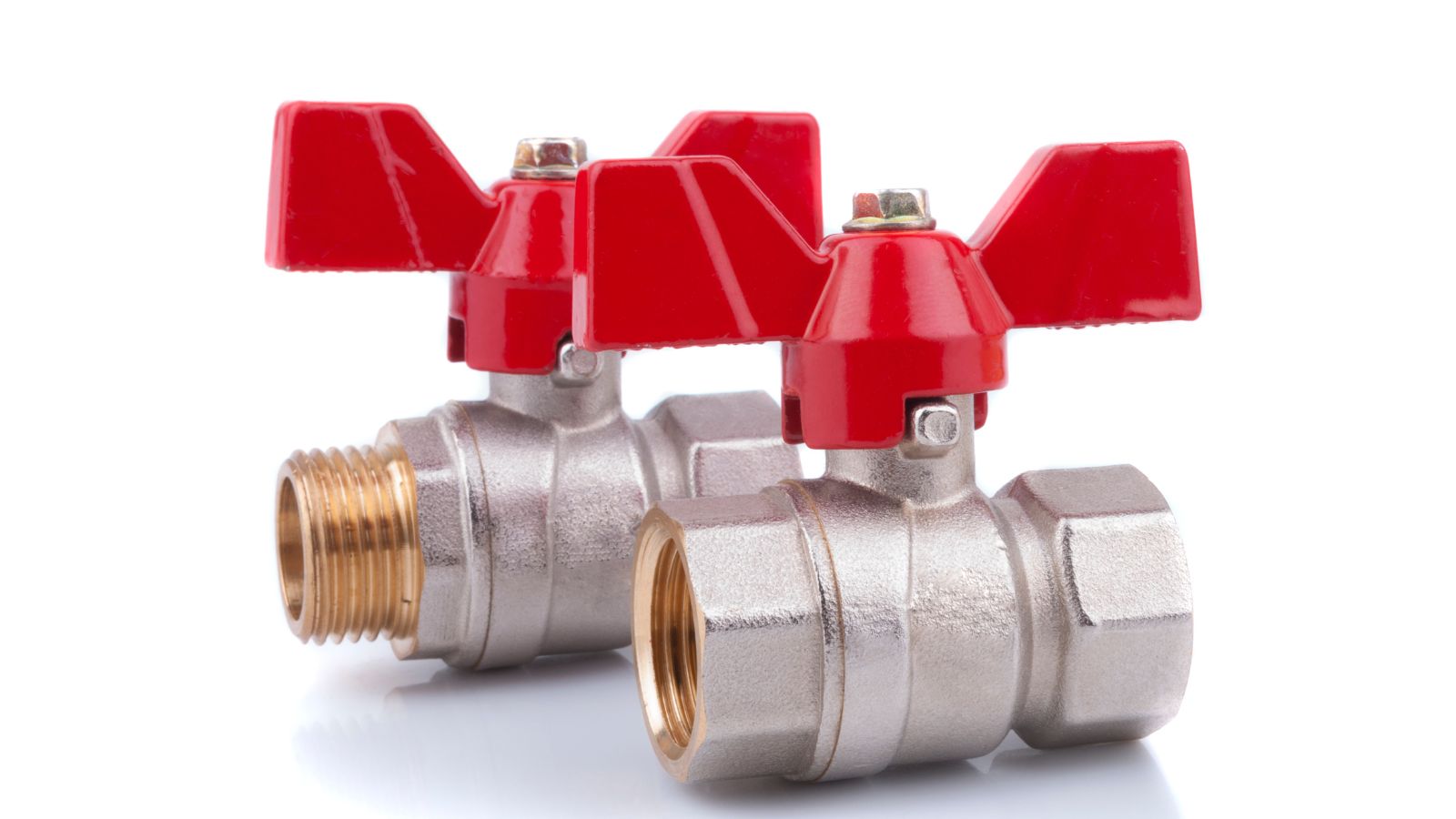

What is a Ball Valve?

A ball valve is named after the ball-like part inside it. This ball has a hole through the middle, and when it is turned, the hole lines up with the pipeline to allow flow. When turned in the other direction, the ball blocks the flow completely.

Ball valves are known for their precise shut-off ability. They can stop the flow instantly when needed, and at the same time, they allow smooth flow when fully open. This makes them useful in projects where full control is important.

What is a Butterfly Valve?

A butterfly valve uses a disc that rotates inside the pipe to control flow. When the disc is aligned with the pipe, fluid passes through freely. When turned, the disc blocks the flow. The design is simple, yet it provides a very effective way of regulating flow.

Butterfly valves are valued for their lightweight structure and compact size. They are easy to operate and can be installed in places where space is limited. This makes them a smart choice in many modern projects.

Choosing Based on Project Needs

Now that you know how both valves work, the question is how to decide which one is better for your project. The answer depends on what your project requires in terms of control, space, and operation.

Both valves offer positive features, so the choice becomes easier when you look at specific needs.

Control and Precision

Ball valves are known for providing precise control. They can shut off flow completely with just a simple turn. This makes them very useful in projects where no leakage can be allowed. For example, in pipelines carrying sensitive liquids or gases, ball valves ensure safety and reliability.

Butterfly valves, on the other hand, are also very good at regulating flow. While they may not provide the same instant shut-off style as ball valves, they are excellent for projects where adjusting flow at different levels is more important than full closure.

Space and Weight Considerations

Another factor to think about is space. Butterfly valves are compact and lightweight. They are easier to install in large piping systems where many valves are required. Because they take up less space, they are often chosen in projects where size and weight matter.

Ball valves are heavier, but they provide strong shut-off ability. If your project has enough space and needs a valve that ensures total closure, ball valves are a smart choice.

Ease of Operation

Both valves are easy to operate, but in slightly different ways. Ball valves use a quarter-turn handle that is simple and quick. Butterfly valves also use a quarter-turn movement, and their simple disc structure makes operation smooth.

For projects where operators need to open and close valves often, both options are user-friendly. The choice depends on whether you prefer the ball’s precise shut-off or the butterfly’s quick flow control.

Applications in Real Projects

To make the decision clearer, it helps to see where each type of valve is commonly used. Both are popular because they fit well into different situations.

Ball Valve Applications

Ball valves are often used in industries that need a tight shut-off. For example, in chemical plants, oil and gas pipelines, or water systems, where safety is a priority. They are also used in residential plumbing because of their reliability.

One of the main strengths of ball valves is that once closed, they do not allow fluid to pass. This makes them excellent for projects where stopping the flow completely is important.

Butterfly Valve Applications

Butterfly valves are popular in water treatment plants, HVAC systems, and large pipelines. Because they are lighter and easier to install, they are often used where many valves are required in one system. Their ability to control flow without taking up much space makes them efficient in large-scale projects.

They are also widely used in industries that handle clean water, air, and light fluids. Their structure makes them cost-effective and reliable for such projects.

Long-Term Use and Reliability

Both ball valves and butterfly valves are built for long-term use. With proper installation and care, they provide years of reliable service. Choosing the right one ensures that your project runs smoothly and without interruptions.

Balancing Performance and Project Goals

When choosing between ball valves and butterfly valves, the main point is to balance performance with project goals. Ball valves give complete shut-off control, while butterfly valves provide smooth flow regulation and save space. Both are positive choices, and the decision should be based on what your specific project requires.

Maintenance and Care

One more thing to note is that both valves are easy to maintain. Regular checks and proper handling keep them in excellent working condition. Their simple operation means less stress on operators, and this adds to the long-term value they provide.

Cost and Efficiency

From an efficiency point of view, both valves are valuable. Ball valves offer safety and precision, while butterfly valves bring lightweight structure and space-saving design. Cost depends on the size of the system and the needs of the project, but in both cases, the investment brings good returns in terms of performance and durability.

Conclusion

Choosing between ball valves and butterfly valves is about matching the valve to your project’s needs. Ball valves are known for complete shut-off and precision, making them perfect for tasks that need maximum control. Butterfly valves are compact and simple, making them ideal for projects that need flow regulation and space efficiency.

Both types of valves are reliable, safe, and built to handle different types of projects. By understanding their strengths, you can make a confident choice that supports your project’s goals. Whether it is for construction, water systems, or industrial plants, ball valves and butterfly valves continue to be essential tools that bring safety, efficiency, and long-term value.